How to choose the right permanent magnets?

There are many types of permanent magnets in the market today such as neodymium iron boron magnets, samarium cobalt magnets, alnico magnets and ferrite magnets. Each type of permanent magnet has its own unique characteristics that affect how well it is used in various applications. For many buyers who are not familiar with permanent magnet materials, it is difficult to choose a suitable permanent magnet to meet their needs.

Therefore, in the following article, the magnet supplier BEARHEART will give you a detailed introduction on how to choose a permanent magnet.

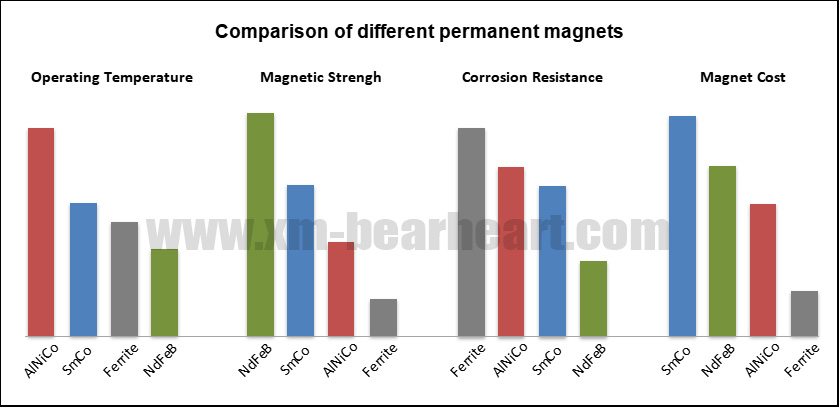

1. Operating temperature

One of the most important parameters when selecting a permanent magnet is the temperature of use.

If you want to choose a permanent magnet with an operating temperature of 500°C, it is recommended that you choose an alnico magnet. It can withstand operating temperatures of 500°C and is the most high temperature resistant magnet material.

If you want to buy a permanent magnet with an operating temperature between 250°C and 350°C, it is recommended that you choose samarium cobalt magnets. This magnet is ideal for working at temperatures of 250°C-350°C.

Ferrite magnets are a good choice if you are purchasing permanent magnets that operate below 300°C. The upper limit of the operating temperature of ferrite magnets is 300°C.

However, if you want to find a permanent magnet suitable for the working temperature of 80℃-230℃, it is recommended that you choose NdFeB. This magnet is suitable for the working temperature of 80℃-230℃ and has strong magnetic force.

2. Magnetic strength

NdFeB magnets are the third generation of rare earth permanent magnet products and are currently the most powerful magnets. They are called strong magnets, or the king of magnets by people. Their (BH)max can reach 52MGOe.

Samarium cobalt magnet

The magnetic force of samarium cobalt magnet is weaker than that of neodymium iron boron magnet. However, samarium cobalt magnets are easier to process into shaped magnets. Its (BH)max is about 26 MGOe.

Alnico magnets

The magnetic force of alnico magnet is weaker than that of samarium cobalt magnet, and its (BH) max is only 5.4MGOe.

Among the four types of permanent magnets we mentioned in this article, the ferrite magnet has the weakest magnetic force, its (BH)max is only 3.6 MGOe.

3.Corrosion resistance

Corrosion can be a concern when choosing a permanent magnet because it can lead to a loss of magnetism in the magnet, which can affect its performance in an application. It can also cause the magnet to weaken or break over time, reducing its lifespan.

Neodymium magnets are highly susceptible to corrosion due to their high iron content (64-68%), making them vulnerable to rust and other forms of corrosion in damp environments.

Suppose a magnet, particularly a NdFeB magnet, will be used in a potentially corrosive environment. In that case, it may be necessary to apply a coating to the magnet to protect it against rust and other forms of corrosion.

Samarium cobalt magnets are much more resistant to corrosion, even when left uncoated. They are also part of the rare earth family of magnets and offer good magnetic performance, although they are not as strong as neodymium magnets.

Alnico and Ferrite magnets are both known for their corrosion resistance, although they do not offer the same level of magnetic performance as neodymium and samarium cobalt magnets.

4. Magnet Cost

Ferrite magnet

Because the raw materials of ferrite magnets are relatively cheap, the price of ferrite magnets is very low, and their market demand is very large, mainly used in handbag factories, speaker factories, leather products factories.

NdFeB magnets

Although the annual output of NdFeB magnets is less than that of ferrite, NdFeB magnets are cost-effective and have the highest output value. They are involved in various industries, mainly used in magnetic connectors, DC motors, robots, smart home and other fields.

Alnico magnets

AlNiCo is the earliest developed permanent magnet material, which is an alloy composed of aluminum, nickel, cobalt, iron and other trace metal elements. Such magnets are relatively expensive and are mainly used in motors, microphones, sensors, speakers, traveling wave tubes, etc.

Samarium cobalt magnet

Samarium cobalt magnet is a magnetic material made of samarium, cobalt and other rare earth metals by mixing, melting and refining into alloys, grinding, pressing and sintering. The cost of producing samarium cobalt magnets is very high. This type of magnet is only used in some high-end permanent magnet motors.

Summarize

Thank you for reading our article, we hope it helps you better understand how to choose the right permanent magnet. If you want to know more about permanent magnets, we recommend you to visit our products for more information.