Permanent magnet materials in automobile EPS

Neodymium Magnets Manufacturer NdFeB Arc Magnetic Materials Permanent Magnet For Motor

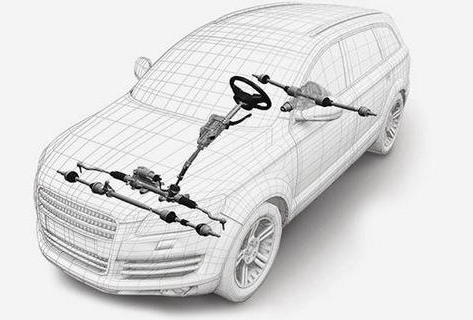

The full name of EPS in English is Electronic Power Steering, which is the electronic power steering system, which uses the power generated by the electric motor to assist the driver in power steering. As an important part of the vehicle, the steering system is one of the key systems that affect the stability, comfort and driving safety of the vehicle.

In the design of steering system, in order to alleviate the contradiction between steering portability and steering sensitivity, most commercial vehicles and 50% of cars adopt power steering system. Since the 1950s, the power steering system has gone through three development stages: conventional hydraulic power steering system (HPS), electro-hydraulic power steering system (EHPS), and electric power steering system (EPS), and continues to be electronic and intelligent Development trend.

From a global point of view, the car EPS loading rate has exceeded 50%. About 63% of the cars sold in my country use HPS in passenger models, and about 35% use EPS. However, the EPS loading rate of my country's self-owned brand cars is only about 20%, and the future development potential is huge. Since 2015, China has surpassed Europe, America and Japan to become the world's largest EPS market.

Composition of EPS system

Based on the traditional mechanical steering system, the EPS electronic power steering system uses the electronic control device to make the electric motor generate auxiliary power of the corresponding magnitude and direction according to the torque signal on the steering wheel and the driving speed signal of the car to assist the driver in the steering operation. It can easily achieve different boosting effects to the electric motor at different vehicle speeds, ensuring that the car is light and flexible when turning at low speeds, and has sufficient road feeling when turning at high speeds, and is stable and reliable.

Although the structural components of different vehicles are different, the structure of the EPS system is generally the same. It is generally composed of a torque (steering) sensor, an electronic control unit, an electric motor, a reducer, a mechanical steering gear, and a battery power supply.

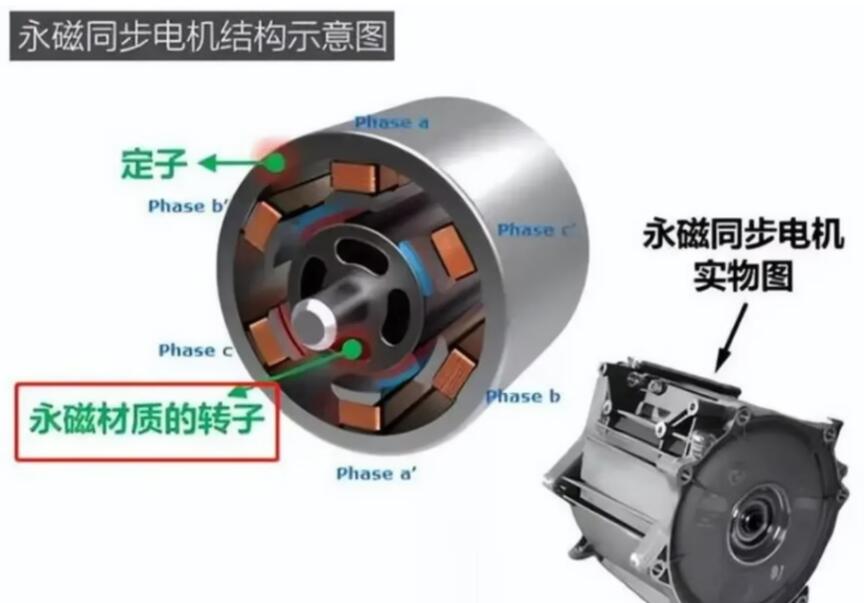

The motors used in EPS are divided into brush motors and brushless motors:

The brushed motor switches the current while the brushes and commutator are rotating, and the power can be turned on. The cost is low, but the windings of the brushed motor are arranged on the rotor side. As the output power increases, the inertia moment of the motor increases. It is necessary to solve the problem of poor steering sensitivity.

The brushless motor itself does not have a rectifying function, so it needs a built-in angle sensor to switch the current corresponding to the angle signal through a circuit, which has a complicated structure and a high cost. However, the windings of the brushless motor are arranged on the stator side, and the rotor is a permanent magnet. Even if the output power increases, the inertia moment problem can be suppressed.

Permanent magnet materials in EPS motors

Rare earth NdFeb permanent magnet is one of the three important components of new energy vehicles different from traditional vehicles, and is also the power source of new energy vehicles. This kind of magnet is the permanent magnet material with the highest magnetic properties found by human beings at present, and is called "super magnet" and "the king of modern permanent magnet".

Ndfeb permanent magnet is a quadripartite crystal formed by neodymium, iron and boron. According to the different production process, it can be divided into sintered NdFeb, bonded NdFeb and hot pressed NdFeb. Because of the different production technology, they have great differences in the magnetic properties of products, after processing and application.

For example, bonded ndFeb is mainly used in fields such as hard disk drive spindle motor and micro special motor with small power, while sintered NdFeb is more used in fields such as drive motor with large power. And the hot pressed NdFeb due to the shape of the restriction, only in the car EPS some use.

EPS has high requirements on the performance, weight and volume of permanent magnet motors. Therefore, the permanent magnet materials mainly use high-performance neodymium iron boron magnets, and currently mainly sintered neodymium iron boron. Common grades are 45H, 48H, 38SH, 40SH, 42SH, 48SH, 35UH, etc. In the future, hot-pressed NdFeB is expected to replace sintered NdFeB in EPS, but the technology is not yet mature and the cost is still high. Sintered NdFeB is still the mainstream.

Thank you for reading our article and we hope it can help you to have a better understanding of the most commonly used rare earth neodymium motor magnets. If you want to learn more about permanent motor magnets, we would like to advise you to visit BEARHEART Magnets for more information.

We can provide high-quality permanent magnets like neodymium magnets, ferrite magnets and magnetic assembly at a very competitive price. Any inquiries and orders are welcomed.