What are the advantages of rubber coated magnets?

Neodymium magnets require surface coating treatment before use due to poor corrosion resistance. If you use the magnet in activities where it may be exposed to moisture, it is best to add a coating to your magnet, otherwise it may corrode. Corrosion will damage the magnet's magnetic field, so coating treatment for the magnet is very necessary.

There are different types of coatings for neodymium magnets, and some mainstream coatings are nickel-copper-nickel, zinc, epoxy, gold, rubber, etc. Each type of coating has its unique characteristics. Today, we mainly introduce rubber-coated magnets, hoping to be helpful to you.

I. What is a rubber-coated magnet?

Rubber-coated magnets, also called encapsulated magnets, commonly use black polyisoprene rubber as a coating to cover the magnet. They are one of the most widely used magnets in various industries. As we all know, rubber-coated magnets are very durable and can provide excellent friction and protection.

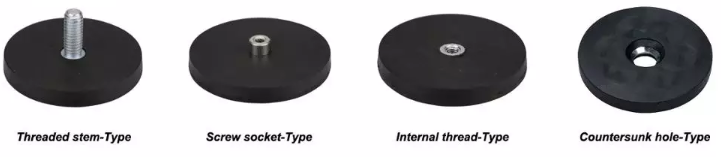

II. Types of rubber-coated magnets

They are very suitable for indoor and outdoor use. Due to their high slip resistance, this type of magnet is usually used for fixing and installation applications. Rubber-coated magnets have different designs, such as external threads, internal threads, countersunk holes, and screw holes.

1. External threads

2. Internal threads

3. Flat threads

4. Counterbore holes

III. Advantages of rubber-coated magnets

1. Strong corrosion resistance

The rubber material itself is corrosion-resistant, and the rubber coating is usually much thicker than other types of coatings for neodymium magnets. This makes this coating suitable for use in humid environments, thus protecting the strong internal magnet.

2. High slip resistance

Rubber has a high coefficient of friction. Common coatings are easily prone to slippage when adsorbed on smooth surfaces, but rubber-coated magnets are not.

3. Good temperature characteristics

Rubber-coated magnets can work normally in high temperatures up to 80 degrees Celsius and low temperatures down to -40 degrees Celsius.

4. Wide variety of colors

The common color is black, but they can also be adjusted to blue, yellow, green, and other colors depending on your needs.

Summary

Rubber-coated magnets are suitable for use in harsh environments, but non-conventional sizes may require mold opening, so it is best to communicate with the magnet factory in advance.

Rubber-coated neodymium magnets are a type of anti-corrosion magnet that typically consists of a neodymium magnet and an outer rubber coating. The rubber coating can effectively protect the magnet from corrosion and damage caused by external environmental factors, extending its service life. Additionally, the rubber coating can improve the magnet's water resistance and friction resistance, making it more suitable for use in wet and high-friction environments.

Rubber-coated neodymium magnets are widely used in various fields, such as medical devices, automotive parts, electronic equipment, motors, sensors, etc. When selecting this type of magnet, it is necessary to consider the requirements of different working environments and the required magnetic force. Furthermore, for some special applications, it is also important to pay attention to temperature and chemical stability. Our company provides a variety of rubber-coated neodymium magnets, which can be customized according to specific customer needs.