5 types of magnetic materials commonly used in new energy vehicles

2023-09-11 13:56Magnetic materials are magnetically ordered materials that have ferromagnetic or ferrimagnetic properties and have practical application value. A fundamental difference between them and other materials is that they are sensitive to external magnetic fields. Broadly defined magnetic materials also include antiferromagnetic materials and other weakly magnetic materials that have practical or possible application value.

In recent years, the overall demand for the magnetic materials industry has increased steadily, and the rapid development of downstream application fields such as optical storage, wind power, new energy vehicles, robots, industrial automation, and wireless charging has brought development opportunities to the magnetic materials industry.

Ⅰ. Metrics for measuring the performance of magnetic materials

The magnetic properties of magnetic materials are measured as follows:

Stability: The main parameters are residual magnetization and maximum magnetic energy product. The higher the value, the stronger the magnetic field and the better the magnet can maintain its magnetic properties.

Demagnetization resistance: The main parameter is the intrinsic coercive force. The higher the value, the stronger the resistance to demagnetization and the higher the efficiency value.

Temperature resistance: The main parameters are intrinsic coercivity, maximum operating temperature, and Curie temperature. The higher the value, the better the temperature resistance and the more stable the magnetic material performance.

Ⅱ. Classification of magnetic materials and their application in new energy vehicles

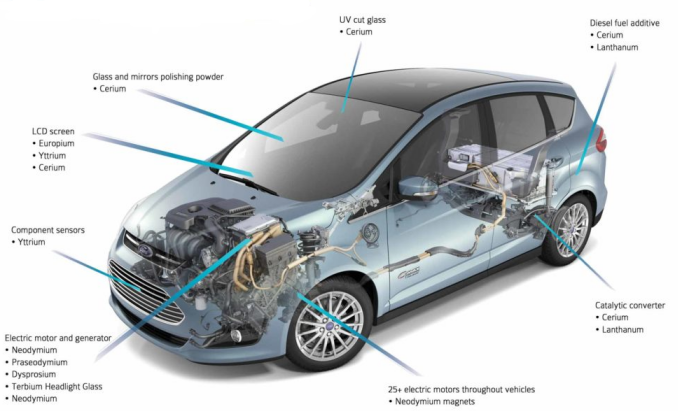

Magnetic materials are divided by function and can be divided into three categories: permanent magnetic materials, soft magnetic materials and functional magnetic materials. At present, the most common applications in new energy vehicles are neodymium iron boron permanent magnets and ferrite permanent magnets among permanent magnet materials, and silicon steel, metal soft magnetic powder cores, ferrite soft magnets among soft magnetic materials.

Neodymium iron boron (Nd-Fe-B) permanent magnet material with Nd2Fe14B as the main component has the characteristics of high remanence and high coercive force. Each new energy vehicle requires approximately 2.5kg of NdFeB permanent magnet materials, which are mainly used for drive motors, ABS, EPS and other components. The material has excellent performance and can greatly improve the energy efficiency of the motor and reduce energy loss. In addition, car speakers and various sensors are also scenarios where iron-iron-boron permanent magnet materials are used in new energy vehicles.

Ferrite permanent magnet materials are made of SrO or BaO and Fe2O3 as raw materials through ceramic technology. Compared with rare earth permanent magnet materials, although ferrite permanent magnet materials do not have an advantage in performance, they are still used in many fields due to their abundant raw materials, low price, simple preparation process, excellent oxidation resistance, and large residual magnetization. is the material of choice. In new energy vehicles, it is mainly used in drive motors, converters, charging piles and other components.

Soft magnetic material-silicon steel

Silicon steel is an iron-silicon alloy formed by adding a small amount of silicon (generally less than 4.5%) to pure iron. It has excellent electromagnetic properties such as high magnetic permeability, low hysteresis loss, and low iron loss. In new energy vehicles, silicon steel is one of the important materials of the motor, which can effectively reduce the iron loss and hysteresis loss of the motor and improve the efficiency and performance of the motor. In addition to motors, silicon steel can also be used in charging piles, battery management systems, body structural parts, etc. of new energy vehicles.

Soft magnetic materials-metal soft magnetic powder core

Metal soft magnetic powder core is a soft magnetic material pressed by magnetic powder coated with an insulating medium. It combines the advantages of metal soft magnetic materials and soft magnetic ferrite. Since its powder is made of ferromagnetic particles, the saturation magnetic induction intensity is high. At the same time, due to the presence of the insulating layer, its resistivity is also high. It is mainly used in three application areas: charging piles, vehicle-mounted AC/DC chargers, and vehicle-mounted DC/DC converters in the new energy vehicle sector. Especially under the trend of 800V high-voltage platform, metal soft magnetic powder core will benefit more, and the usage of bicycles is expected to increase from the current about 0.7kg to 2.7kg.

Soft magnetic material-ferrite

Soft ferrite is a ferrimagnetic oxide mainly composed of Fe2O3, which is produced using powder metallurgy methods. There are several types such as Mn-Zn, Cu-Zn, Ni-Zn, etc., among which Mn-Zn ferrite has the largest output and usage. As an electronic functional material with excellent high-frequency electrical properties, relatively low cost, and easy processing into products of different shapes and sizes, soft ferrite is widely used in new energy vehicle OBC equipment, EV charging equipment, HEV power system power conversion, DC -DC converters, battery management systems, power distribution units, etc.

Ⅲ. Application prospects of magnetic materials in new energy vehicles

The industrialization of magnetic materials in China began to take shape in the mid-to-late 1980s. Mainly due to the popularity of electronic products such as tape recorders and televisions, the demand for magnetic materials used in audio speakers has increased rapidly.

Today, the booming development of new energy vehicles has brought huge development space to magnetic materials. According to data from the China Association of Automobile Manufacturers, my country's new energy vehicle production and sales in Q1 2023 will reach 1.65 million and 1.586 million respectively, a year-on-year increase of 27.7% and 26.2% respectively, with a market share of 26.1%. The development of my country's new energy vehicle industry has entered the A new stage of rapid development of scale. Regardless of the future downstream share or growth rate of key magnetic materials, the development of the new energy vehicle field is of great importance and has far-reaching influence.

As the basic core material of key electronic components, magnetic materials are widely used in all aspects of new energy vehicle drive motors, charging piles, battery management systems, AC/DC chargers, DC/DC converters and other components. Stimulated by demand, the number of domestic enterprises engaged in the production and manufacturing of magnetic materials continues to increase, and a complete range of magnetic material product systems have now been formed. As a subdivision of new energy vehicle magnetic materials, market competition is also fierce. Among them, companies with greater competitive advantages mainly include Jinli Permanent Magnet, Tiantong Co., Ltd., Zhenghai Magnetic Materials, Yingluohua, Galaxy Magnet, Sinosteel Tianyuan, Hengdian East Magnet, Jiangfen Magnetic Materials, Ningbo Yunsheng, Zhongke San Ring etc. As the country vigorously advocates energy conservation and environmental protection and the development of new energy vehicle technology, my country's magnetic materials industry still has great development potential.