Market analysis of permanent magnet material industry

2023-03-27 11:3301

Overview of the permanent magnet material industry

1. Overview of permanent magnet materials

Magnetic materials are materials that can react to magnetic fields in a certain way. According to the degree of magnetization, they can be divided into permanent magnet materials and soft magnetic materials. Permanent magnet materials, also known as hard magnetic materials, are mainly characterized by their high magnetic property and high coercivity. After removing the external magnetic field, they can still maintain high magnetism for a long time. Common permanent magnet materials are divided into aluminum-nickel-cobalt permanent magnet alloy, fe-chrome-cobalt permanent magnet alloy, permanent magnet ferrite, rare earth permanent magnet material and composite permanent magnet material, etc.

Metal permanent magnet materials developed earlier, originated from carbon steel in the early 20th century, mainly used in the field of instrumentation, but with the emergence of new permanent magnet materials, the output gradually decreased. Ferrite permanent magnet material is made of strontium oxide or barium oxide plus ferric oxide as raw material by ceramic production process, including sintered ferrite magnet and bonded ferrite magnet, mainly used in household appliances, printers, sensors, toys and other fields.

Rare earth permanent magnet materials have many advantages, such as high crystal anisotropy, high saturation magnetization, high coercivity and high magnetic energy product. The current NdFeb magnetic material is the third generation of rare earth permanent magnet material, which is the generation with the best comprehensive performance. Ndfeb has very high magnetic energy product and coercivity, as well as the advantages of high energy density, making NdFeb magnetic material widely used in modern industry. At present, new energy vehicles, rare earth permanent magnet motors, wind power and so on are the main application fields.

2. Industry classification of permanent magnet materials

Rare earth permanent magnet material refers to the permanent magnet material containing rare earth metals. It is a kind of magnetic material produced by the alloy composed of rare earth metals, such as neodymium and samarium, and transition metals, such as cobalt and iron, which are pressed and sintered by powder metallurgy method and magnetized by magnetic field. The birth of rare earth permanent magnet material is a major advance in the field of magnetic materials, which makes magnetic devices in the high-tech industry high efficiency and light. At present, it is mainly divided into samarium cobalt permanent magnet and NdFeb permanent magnet according to different downstream applications. The fourth generation of rare earth fe-nitrogen permanent magnet is still under active research and development.

The first and second generation of rare earth permanent magnet materials - samarium cobalt permanent magnet. Samarium cobalt permanent magnets are mainly made by matching rare earth elements samarium, cobalt and other elements. At present, samarium cobalt permanent magnets are mainly divided into the first generation SmCo5 (type 1:5) and the second generation Sm2Co17 (2: 17) type two, taking the second generation of samarium cobalt permanent magnets as an example, in which the proportion of cobalt is 48%-52%, samarium is 23%-28%, and iron is 14%-17%. Samarium cobalt permanent magnet is characterized by high magnetic properties and better high temperature resistance than NdFeb permanent magnet. However, due to the high proportion of cobalt, and the cost price of cobalt is higher than that of neodymium, there are relatively few downstream applications at present, mainly in the fields of national defense, aerospace, communication technology and so on.

The third generation of rare earth permanent magnet material - NdFeb permanent magnet. At present NdFeb permanent magnet is the permanent magnet material with the best performance, the largest consumption and the highest proportion of the magnetic material market. Neodymium accounted for 29%-32.5%, iron accounted for 64%-69% and boron accounted for 1.1%-1.2% in NdFeb magnetic materials. In recent years, due to the high cost performance of ndfeb magnetic materials, as well as the continuous optimization of the production process of the magnetic materials, the production and application of NdFeb magnetic materials have been rapid development. The energy density and coercivity of Ndfeb magnetic material are very high, and has strong magnetic and mechanical properties. The disadvantage is that the high temperature resistance is poor, and it is easy to powder corrosion. According to industry practice, sintered NdFeb permanent magnet materials whose intrinsic coercivity (Hcj, kOe) and maximum magnetic energy product ((BH) max, MGOe) are more than 60 belong to high-performance NdFeb permanent magnet materials. At present, high-performance Ndfeb magnetic materials are mainly used in new energy vehicle drive motor, rare earth permanent magnet motor, direct drive wind power permanent magnet motor and other fields. In the future, with the rapid growth of production and sales of new vehicles, the popularity of permanent magnet motor and other downstream drive, the demand for NdFeb magnetic materials will increase significantly.

Bonded NdFeb, sintered NdFeb, hot pressed NdFeb. Contemporary ndfeb magnetic materials are mainly divided into bonded ndFeb and sintered NdFeb. The difference between the two mainly lies in the difference in process. Bonded ndfeb is injected with adhesive in NdFeb magnetic powder, and then processed through the molding process of various plastic materials. At present, it is mainly used in hard disk drive magnets, automotive motors and magnetic sensors and other kinds of industrial and household motors.

Sintered NdFeb is the use of powder metallurgy process, the melting and casting furnace body vacuum, through high temperature heating molding. The main downstream applications include rare earth permanent magnet motors, loudspeakers, magnetic separators, computer disk drivers, magnetic resonance imaging equipment and meters. Due to the difference in magnetic and molding methods, the intersection of bonded ndfeb and sintered NdFeb is not much. Sintered NdFeb is widely used in the field of driving motor with large power due to its high magnetic energy product and cost performance. Bonded NdFeb has the characteristics of simple process and small size, and is more used in the field of micro motor.

Ndfeb is a magnet with high magnetic properties made by hot extrusion and hot deformation process. It has the advantages of high density, high orientation, good corrosion resistance, high coercivity and near final forming. At present, only a few companies have mastered the production process, patent barriers and production costs are high, and the total output is relatively small.

02

Market analysis of permanent magnet material industry

In 2021, the output of main rare earth permanent magnet materials increased rapidly, among which the output of sintered ndFeb blank was 207,100 tons, up 16% year on year. The yield of bonded Ruiron boron was 9380 tons, with a year-on-year increase of 27.2%; The output of samarium cobalt magnets was 2,930 tons, up 31.2 percent year-on-year. Sintered ndFeb is the most productive and widely used rare earth permanent magnet material in our country.

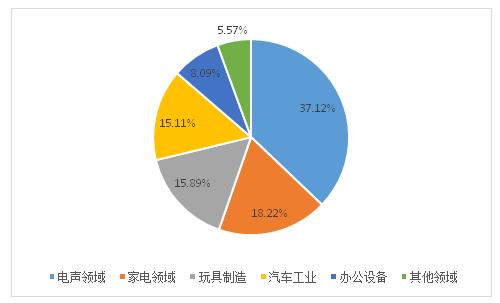

Magnetic materials are widely used in consumer electronics, household appliances, automobile industry, wind power generation, aerospace and other industrial fields. As an important branch of magnetic materials industry, the permanent magnet material industry has huge market potential and development space. In recent years the output of permanent magnet ferrite magnet in our country was about 500000 tons every year. According to the data, the permanent magnet ferrite market accounted for 37.12% in electroacoustic field (including consumer electronics), 18.22% in household appliances, 15.89% in toy manufacturing, 15.11% in automobile industry, 8.09% in office equipment and 5.57% in other fields.

03

Development trend analysis of permanent magnet material industry

1. Industrial policies have long supported and promoted industrial development

High performance permanent magnet material belongs to the key new materials and high-tech products, has long been supported by the national industrial policy. The implementation of relevant policies will further promote the improvement of the overall product quality in the market, drive the entire industry to high-end and intensive quality and service competition, improve the downstream market space and product demand, and promote the healthy development of the industry.

2. The urgent demand for green industry and energy-saving products accelerates the development of the industry

As industrialization and urbanization accelerate and consumption structure continues to upgrade, the demand for energy rigid growth, resources and environment problems are still one of the bottlenecks restricting economic and social development, energy conservation and emission reduction is still a serious situation. As an important basic functional material for green energy-saving industry such as energy-saving household appliances, energy-saving motors and new energy, permanent magnet material is of great significance for realizing the development goals of green energy saving in our country. The downstream demand for energy-saving products will drive the rapid development of permanent magnet industry.

3. The chain development of the rare earth industry promotes the international competitiveness of the industry

After decades of development, the strength of development and utilization of rare earth has been improved in a comprehensive way. We have formed an independent and complete industry chain of rare earth, accumulated rich advanced technologies of the whole industry chain, and become capable of transforming resource advantage into competitive advantage in the market. As an important link in rare earth industry chain, Chinese rare earth permanent magnet industry has also formed a relatively complete subdivision industrial system. The advantage of the whole industry chain is conducive to the promotion of international competitiveness of industry.

4. The technical level of the industry has improved significantly

In the early 1990s, our country immediately followed Japan, Europe and the United States and began to conduct research on permanent magnet material, and experienced a development stage in technology from scratch. On the basis of their long-term research and development, leading domestic enterprises continue to innovate advanced production technology, production technology and management methods, forming a unique process technology and quality management control system with Chinese characteristics, and in the quick setting process, crushing and pulverizing technology and other key technologies of kiloton level breakthrough, close to the international leading level represented by Japanese enterprises. International competitive advantage gradually emerged.

5. High market demand for high-performance products provides development opportunities for the industry

As consumer electronics, energy-saving household appliances, industrial motors, wind power generation and automotive industries enter a period of rapid development, high-performance permanent magnet materials show broad application prospects, market demand is increasingly strong, is expected to usher in a period of explosive demand. Under the continuous pull of new energy vehicles, industrial motors, wind power generation, traditional automobiles, frequency conversion air conditioning, consumer electronics, rail transit and industrial robots and other fields, superposed by the strong support of the "double carbon" policy, the future demand space of rare earth permanent magnet materials has been fully opened, which provides opportunities for the growth of domestic high-quality enterprises.