Cast AlNiCo Cylinder Magnet for Sensors

We can supply all grades of Alnico magnets, For example: Alnico2,3,4,5,8...

The higher the performance level, the stronger the magnetic force

*AlNiCo2,AlNiCo3--450°C (842°F)

*AlNiCo5DG,AlNiCo5-7,AlNiCo6--525°C (977°F)

*AlNiCo8,AlNiCo8HC,AlNiCo9--550°C (1022°F)

If you are not sure which grade is appropriate, please feel free to contact us.

- Information

Wholesale powerful strong permanent alnico magnet cylinder magnet

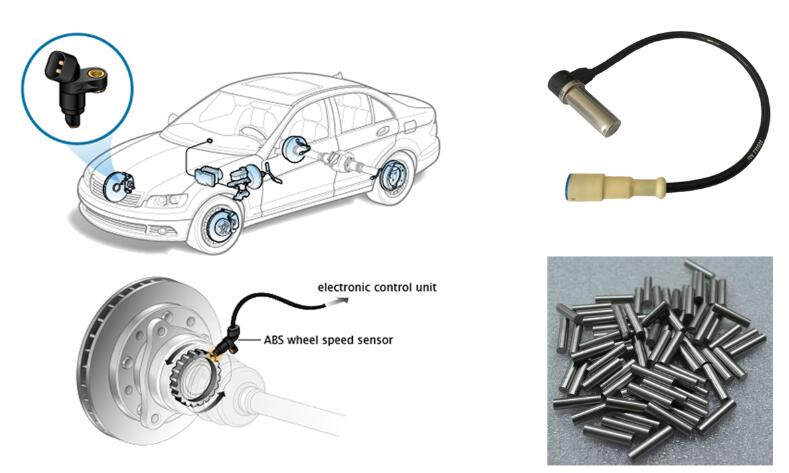

Cast Alnico magnet is composed primarily of Aluminum, Nickel, Cobalt, Copper and Iron. It has very good corrosion resistance and high temperature operation. Although other magnetic materials offer greater energy and coercivity values, the high remanence and thermal stability of AlNiCo makes it the most effective magnetic material for certain applications, like sensors, generator, microphone, lifting, voltmeter and measuring instruments. It is widely applied in high stability fields like aerospace, military, automobile and security systems.

Magnetic Feature

1. Good chemistry stability and strong anti-corrosion

2. Excellent stability and magnetic performance

3. Various shapes and size

4. High working temperature

5. Strong magnetic force

6. High intrinsic coercive force

Neodymium sensor magnets

Besides wheel speed sensor, there're thousands of applications for sensor magnet, which require neodymium magnets. Such as hall effect sensor, float sensor, Reed sensor and so on.

Here below is the size range for Neodymium sensor magnets( also can be customized).

Description | Dimension(mm) | Grade | Max working temperature(℃) |

Block sensor magnets | 7.62*3.18*3.18 | N45H | 120 |

19.05*3.18*3.18 | N35H | 120 | |

21.00*7.00*4.70 | N35H | 120 | |

Disc sensor magnets | 6.35*6.35 | N35H | 120 |

4.4*6.00 | N35SH | 120 |

Custom Permanent Magnets for Sensor Applications

Bearheart provides rare earth magnets (Samarium–Cobalt & Neodymium), hard ferrite and AlNiCo permanent magnet, molded magnets for sensor applications. They all come in different sizes and shapes. Meanwhile, they have different magnetic strengths.

Different types of sensors and different working environments require different permanent magnets. Because of magnet’s properties, it should be fully considered a shock, vibration, strong external magnetic fields as well as high temperatures in the design of sensor magnet. All these factors will influence the magnetic force and the long term stability in different ways.

The sintered neodymium magnet is the strongest magnet. The rare earth smco magnets combine high magnetic force and high working temperature. Alnico magnets are the most stable magnet and can work up to 550°C. Ferrite magnets are the cheapest magnet and their coercivity is higher than alnico magnets. Molded magnets are best for the multi-poles requirement and they are customized in various material, shapes and sizes.

FAQ:

Q1. What are Alnico magnets?

A1. Alnico magnets are made from a combination of aluminum, nickel, cobalt, and iron. They are known for their high magnetic strength and are often used in industrial applications.

Q2. What are Alnico magnets used for?

A2. Alnico magnets are used in a variety of applications such as electric motors, generators, sensors, speakers, and holding magnets. They are popular because they are strong and durable.

Q3. What are the benefits of using Alnico magnets?

A3. Alnico magnets have a high magnetic strength and are resistant to demagnetization. They can also withstand high temperatures and are durable, making them a popular choice for industrial applications.

Q4. How do you determine the strength of an Alnico cylinder magnet?

A4. The strength of an Alnico cylinder magnet is determined by its grade, or quality, which is indicated by a letter designation. The higher the grade, the stronger the magnet.

Q5. What is the maximum operating temperature for an Alnico cylinder magnet?

A5. The maximum operating temperature for an Alnico cylinder magnet is typically around 500-550°C (930-1020°F), although this may vary depending on the specific grade of the magnet.