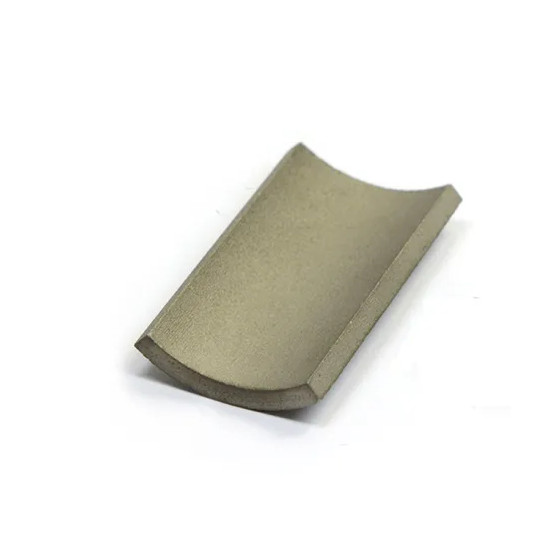

Rare Earth Smco Arc Magnets

Specifications

1. SmCo magnet, permanent magnet, rare earth magnet

2. Excellent resistance to corrosion, high working temperature.

Our SmCo Magnet can be produced in a variety of shapes sizes and grades as part of our SmCo magnets (made-to-order) custom service.

- Information

Customized Sintered SmCo Samarium Cobalt Magnet china supplier

Samarium cobalt magnet is mainly formed by the metal samarium, cobalt and some other rare earth elements of the permanent magnet.It has a high magnetic energy product, super low temperature coefficient,and the operating temperature can up to 300 ℃.At the same time, it has a strong corrosion resistance and oxidation resistance. Therefore, SmCo magnetic steel usually does not need to be electroplated, and is widely used in motors, meters, sensors, engines, radar and for other high-tech fields.

SmCo Arc Magnet is a common shape of SmCo Rare earth magnets. SmCo Magnets are perfect for high temperature application, as they can work properly at 250-300 °C. We provide SmCo Arc Magnets for various applications.

Product Description

Item Name: Sm2Co17 SmCo Arc Magnets for Motors

Grade: m2Co17

Size: R50xr35x30mm - 45°( +/-0.05mm )

Coating: NiCuNi, Zinc, Epoxy or so on

Carton Size: 35*25*15cm

Magnetization: As Customer's Requirement

Sample Time: About 30 Days

Working Temperature: 350 ºC

Main Processing: Vacume Sintered

Tolerance: +/-0.1 mm

Basic properties of Samarium cobalt magnet

– the main element is samarium, cobalt, and some other trace elements

– high temperature sintering (Shaped by mold firstly, than sintered by high temperature)

– SmCo Magnet material is bright gray, usually be plated by nickel

– The maximum operating temperature is up to 250-300 ℃, it is suitable for many kinds of high-performance motor

– mainly divided into two types of 1: 5 (SmCo5) and (Sm2Co17)

– samarium cobalt magnets are mostly in round shape.The thickness is 1/8 of the diameter, and be magnetized through thickness.

parameters | SmCo5 | Sm2Co17 |

αBr (%/ ℃ ) | -0.04 | -0.03 |

αHcj (%/ ℃ ) | -0.3 | -0.2 |

Curie temperature(℃) | 700-750 | 800-850 |

density (g/cm3 ) | 8.2-8.4 | 8.3-8.5 |

Webster hardness (HV) | 450-500 | 500-600 |

Working temperature ( ℃ ) | 250 | 350 |

SmCo Arc Magnet for generator and electric motor

Compared to the traditional motor, rare-earth magnet coreless motor with high efficiency, light weight, small size, good speed control, reliability, etc. can be widely used in wind power, electric vehicles, industrial motors, and other fields. In the low-carbon energy saving background, samarium cobalt market is very large. Currently, in Japan and Europe and other countries use about 98% of the air-conditioning inverter air conditioner, but China seldom uses. the inverter air conditioner has comfortable, energy-saving features will

become a trend in the future.

FAQ:

Q1. What is a Samarium Cobalt magnet?

A1. A Samarium Cobalt magnet (SmCo) is a type of rare earth magnet made from an alloy of the elements Samarium and Cobalt, along with traces of other elements.

Q2. What are the characteristics of SmCo magnets?

A2. SmCo magnets are known for their high magnetic strength, excellent temperature stability, and high resistance to demagnetization. They are also brittle and relatively expensive compared to other types of magnets.

Q3. What are the applications of SmCo magnets?

A3. SmCo magnets are used in various industrial applications, including sensors, motors, actuators, and generators, where high magnetic strength and temperature stability are required.

Q4. How are SmCo magnets made?

A4. SmCo magnets are manufactured through a process called powder metallurgy, which involves the mixing of raw materials, pressing them into the desired shape, and then sintering the magnet in a furnace.

Q5. What are the advantages of SmCo magnets?

A5. SmCo magnets have high magnetic strength, excellent temperature stability, and high resistance to demagnetization. They are also resistant to corrosion and do not require coatings.