What are alnico magnets?

What are alnico magnets?

Aluminum Nickel Cobalt (AlNiCo) is the first permanent magnet material developed. It is an alloy composed of aluminum, nickel, cobalt, iron and other trace metal elements. The AlNiCo permanent magnet material was successfully developed in the 1930s. At that time, it had the best magnetic properties and a small temperature coefficient, so it was used the most and most widely in permanent magnet motors. After the 1960s, with the advent of ferrite permanent magnets and rare earth permanent magnets, the application of AlNiCo permanent magnets in motors has gradually been replaced, and the proportion of them has shown a downward trend.

Common Characteristics of Alnico magnets?

1. Very temperature stable, great for high heat applications

2. Wide range of working temperatures, up to 550ºC

3. May be ground to size

4. Does not lend itself to conventional machining (hard and brittle)

5. High residual induction and energy product compared to ceramic material

6. Low coercive force compared to ceramic and rare earth materials (more subject to demagnetization)

How alnico magnets are made?

AlNiCo magnets can be classified to cast magnets and sintered magnets according to the manufacturing technology.

Alnico magnets are produced by casting or sintering processes. Cast alnico is produced by conventional methods using resin bonded sand molds. Sintered alnico magnets are formed using powdered metal manufacturing methods. Sintering alnico is suitable for complex geometries

Alnico magnets produced by casting are greater in density and mass, which gives them better magnetic characteristics and performance. However, sintered Alnico magnets are more economical to produce. Both anisotropic and isotropic variations of Alnico magnets can be produced by sintering or casting.

Magnetic Properties of Cast AlNiCo Magnets

Grade | Remanence Br | Coercivity Hcb | Max. Energy Product (BH)max | Temp. Coefficient Tk | Curie Temp. | Max. Operating Temperature | MMPA Equivalent | ||||

mT | Gs | kA/m | Oe | kJ/m3 | MGOe | %/℃ (Br) | %/℃ (Hcj) | ℃ | ℃ | ||

LN10 | 600 | 6000 | 40 | 500 | 10 | 1.2 | -0.02 | -0.03 | 810 | 450 | AlNiCo3 |

LNG12 | 700 | 7000 | 44 | 550 | 12 | 1.5 | -0.02 | -0.03 | 810 | 450 | AlNiCo2 |

LNG13 | 680 | 6800 | 48 | 600 | 13 | 1.63 | -0.02 | -0.03 | 810 | 450 | |

LNG18 | 900 | 9000 | 48 | 600 | 18 | 2.25 | -0.02 | -0.03 | 850 | 450 | AlNiCo4 |

LNG37 | 1200 | 12000 | 48 | 600 | 37 | 4.63 | -0.02 | -0.03 | 860 | 525 | AlNiCo5 |

LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5 | -0.02 | -0.03 | 860 | 525 | |

LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.5 | -0.02 | -0.03 | 860 | 525 | |

LNG52 | 1300 | 13000 | 56 | 700 | 52 | 6.5 | -0.02 | -0.03 | 860 | 525 | AlNiCo5DG |

LNG60 | 1330 | 13300 | 60 | 750 | 60 | 7.5 | -0.02 | -0.03 | 860 | 525 | AlNiCo5-7 |

LNGT18 | 580 | 5800 | 90 | 1130 | 18 | 2.25 | -0.02 | -0.03 | 860 | 550 | AlNiCo7 |

LNGT28 | 1000 | 10000 | 58 | 720 | 28 | 3.5 | -0.02 | -0.03 | 860 | 525 | AlNiCo6 |

LNGT32 | 800 | 8000 | 100 | 1250 | 32 | 4 | -0.02 | -0.03 | 860 | 550 | AlNiCo8 |

LNGT38 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | -0.02 | -0.03 | 860 | 550 | |

LNGT44 | 850 | 8500 | 120 | 1500 | 44 | 5.5 | -0.02 | -0.03 | 860 | 550 | |

LNGT48 | 900 | 9000 | 120 | 1500 | 48 | 6 | -0.02 | -0.03 | 860 | 550 | |

LNGT60 | 950 | 9500 | 110 | 1380 | 60 | 7.5 | -0.02 | -0.03 | 860 | 550 | |

LNGT72 | 1050 | 10500 | 112 | 1500 | 72 | 9 | -0.02 | -0.03 | 860 | 550 | AlNiCo9 |

LNGT88 | 1100 | 11000 | 115 | 1450 | 88 | 11 | -0.02 | -0.03 | 860 | 550 | |

LNGT36J | 700 | 700 | 140 | 1750 | 36 | 4.5 | -0.02 | -0.03 | 860 | 550 | AlNiCo8HC |

Magnetic Properties of Sintered AlNiCo Magnets

Grade | Remanence Br | Coercivity Hcb | Max. Energy Product (BH)max | Temp. Coefficient Tk | Curie Temp. | Max. Operating Temperature | MMPA Equivalent | ||||

mT | Gs | kA/m | Oe | kJ/m3 | MGOe | %/℃ (Br) | %/℃ (Hcj) | ℃ | ℃ | ||

FLN8 | 500 | 5000 | 40 | 500 | 9 | 1.13 | -0.02 | -0.03 | 760 | 450 | AlNiCo3 |

FLNG12 | 700 | 7000 | 48 | 600 | 12.4 | 1.55 | -0.02 | -0.03 | 810 | 450 | AlNiCo2 |

FLNGT18 | 600 | 6000 | 90 | 1130 | 18 | 2.2 | -0.02 | -0.03 | 860 | 450 | AlNiCo7 |

FLNG34 | 1200 | 12000 | 48 | 600 | 34 | 4.25 | -0.02 | -0.03 | 890 | 450 | AlNiCo5 |

FLNG37 | 1250 | 12500 | 48 | 600 | 37 | 4.63 | -0.02 | -0.03 | 890 | 450 | AlNiCo5 |

FLNGT28 | 1050 | 10500 | 60 | 600 | 28 | 3.5 | -0.02 | -0.03 | 850 | 450 | AlNiCO6 |

FLNGT38 | 800 | 8000 | 120 | 1500 | 38 | 4.75 | -0.02 | -0.03 | 850 | 450 | AlNiCo8 |

FLNGT42 | 880 | 8800 | 120 | 1500 | 42 | 5.25 | -0.02 | -0.03 | 820 | 450 | AlNiCo8 |

FLNGT36J | 700 | 7000 | 140 | 1750 | 33 | 4.13 | -0.02 | -0.03 | 850 | 450 | AlNiCo8HC |

The above-mentioned data of magnetic properties and physical properties are given at room temperature.

The max working temperature of magnet is changeable due to length-diameter ratio, coating thickness and other environment factors.

What are alnico magnets used for?

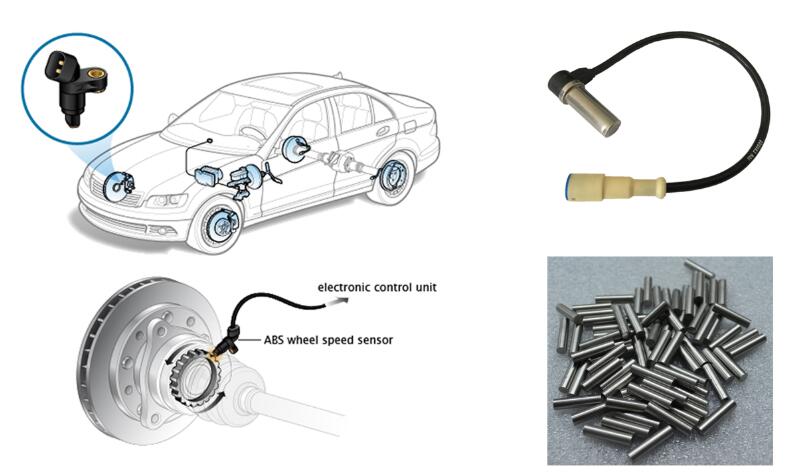

· Guitar pick-ups · Security sensors · Coin acceptors · Relays · Controls · Cow magnets · Jigs & fixtures, holding and Gripping applications

· Educational facilities · Experimental applications