Black Epoxy Coated Countersunk Neodymium Magnet

The countersunk hole allows straightforward attachment to almost any material such as wood, plastic and masonry, to name just a few. Simple to attach with a flat head screw, the tapering screw head sits flush inside the countersunk magnet for seamless professional finish. These magnets can also be recessed into timber or plastic and secured with a countersunk screw for a permanent result without the need to use messy glue. Glue can perish or discolour with age however screws stay true, making them the ultimate fixing solution.

- Information

Wholesale Custom Strong Rare Earth NdFeb Black Epoxy Round Disc Neodymium Magnets

Countersunk magnets are extremely popular neodymium magnets which have a central countersunk hole to allow the magnet to be easily fastened into place with a screw, leaving the screw head flush with the magnet. They are great for hanging signs, tools, etc. These screw-on magnets are very popular for kitchen installations, retail store shelving, furniture and many other applications.

Epoxy is the most corrosion resistant of the neodymium coating options. The coating gives the countersunk neodymium magnets a deep, black finish. Epoxy coated magnets are your best option if you will be using the magnets outdoors or in a humid environment. Black epoxy could protect magnets from corrosion and abrasive wear. A multitude of benefits exist including home projects, crafts, aquariums, hanging accessories/picture frames, and fastening objects together.

Products description

1. Item Name: black epoxy coated countersunk neodymium magnets

2. Material: Neodymium-Iron-Boron

3. Various shapes on offer: block, round, ring, arc - even highly complex forms. Virtually any shape of black epoxy coated countersunk neodymium magnets can be made to your requirements!

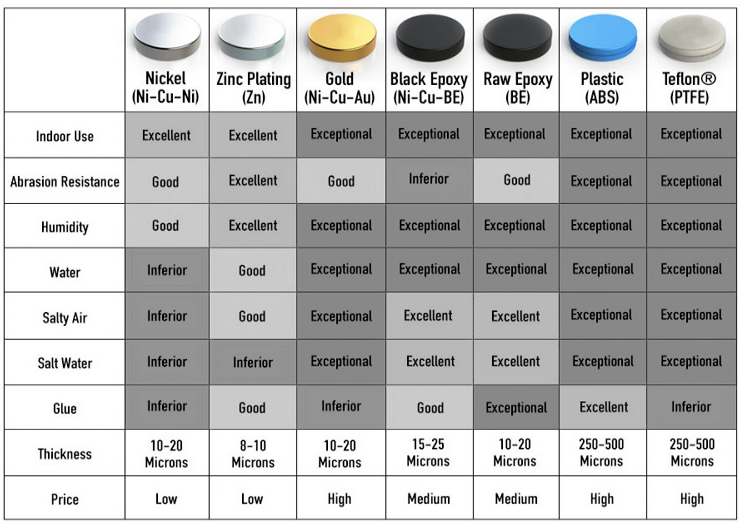

4. Coatings: Nickel, Zinc, Chromium, Epoxy, Gold, Silver, Parylene, Everlube, Passivation, Copper, Chemical, PTFE and more.

5. Max. working temperature for various grades of black epoxy coated countersunk neodymium magnets:

Features

About Epoxy resin (Ni-Cu-Ni-Epoxy)

Colour: black almost 100% non-corrosive, as long as the coating is intact, not shock-resistant (crumbles quickly)

Thickness: approx. 10 micrometer Even the smallest, not visible to the eye, damages of the coating will cause damage to the magnet in the long term when exposed to moisture.

Related Products

Neodymium (Rare Earth) Pots, Hooks, Eye Bolts

Neodymium mounting magnets come in a variety of sizes and shapes, with countersunk holes, straight center holes, male thread, female thread, a threaded hook, or threaded eye bolt. These versatile magnets are used in many commercial and industrial applications such as keeping doors open or closed, cabinetry, holding, fixing, attaching objects to walls, ceilings, vehicles or any ferrous metallic object or surface. Our mounting magnets are high strength rare earth magnets in a mild steel cap for extra protection against chipping or cracking. They are single-sided magnets that can be attached to non-magnetic surfaces without damaging the surface. We can also custom manufacture neodymium block magnets to your exact specifications, just send us a special request and we'll help you determine the most cost effective solution for your project.

FAQ:

Q1. Do you provide samples ? is it free or extra ?

A1. Yes, we could offer the sample for free charge if we have stock.

Q2. Do neodymium magnets lose strength over time?

A2. They don't naturally lose any strength and will keep the strength permanently in the normal conditions, unless meet the high temperature over 80 degrees Celsius(℃), and then will lose the strength gradually.

Q3. What is the best coating for neodymium magnets?

A3. The most common type of coating for neodymium magnets is nickel. These magnets feature a thin layer of nickel over the neodymium material. Nickel is naturally resistant to oxidation. As a result, it's often used for neodymium magnet coatings as well as electroplating applications.

Q4. What is the coating on neodymium magnets?

A4. The typical coating for a neodymium magnet is a layer of nickel followed by a layer of copper and then nickel again. However there are many different coatings used with neodymium magnets including gold, rubber and Polytetrafluoroethylene (PTFE).

Q5. What are countersunk magnets used for?

A5. Basically, countersunk magnets are good for whenever you need to securely fasten a magnet to an object or surface. Gluing magnets works, but sometimes you need something more rigid, which is where countersunk magnets are great.